Arrival Of A New Toy

This past week, we took delivery of a much anticipated piece of machinery in our factory that will help our supply chain become even more streamlined in the months ahead. This giant piece of equipment, called a “vibe deburring” machine, eliminates the need to send our raw products outside of the company for an intermediate step of finishing. Moving this process inside our plant allows us to better control leadtimes and supply of product into our manufacturing cycle.

Nordic Ware’s brand name is synonymous with cast aluminum kitchenware products, which we’ve been producing since the company was first conceived in 1946. Over the years, we’ve perfected the process and have become recognized in our industry as the expert in aluminum casting. Thus, it’s important for us to produce parts that meet very stringent quality standards so as to uphold our reputation. While Nordic Ware makes products out of many other materials besides cast aluminum, this vibe deburr machine will only be used to process cast parts. Why? As die casting molds are used over time, what begins as highly polished surfaces inside the tools begin to wear down. They can be polished and refinished, but only to a certain extent. We can prolong the life of a tool by adding a processing step through a vibe deburr machine or by hand-sanding each part. Whereas in the past we have been sending parts to outside vendors to have this process applied or doing hand finishing in house (time consuming!), we are now able to complete the vibe deburr process in house, saving time, cutting down on transportation, and creating a new job!

So you’re probably curious what a machine like this does? The easiest thing to liken it to is a giant version of a rock tumbler from your childhood. Remember how you would load rough stones into your tumbler, add grit, and let them roll around for days to soften sharp edges? There aren’t as many steps in our vibe deburring process as there are in rock polishing, but the ingredients and physics of the process have some similarities. Our vibe deburr machine spans two rooms in our factory, so it’s difficult to get a photograph of it in its entirety. In lieu of that, here’s a photo of what our machine would look like if it were standing alone. It’s over 50 feet long and 10 feet high!

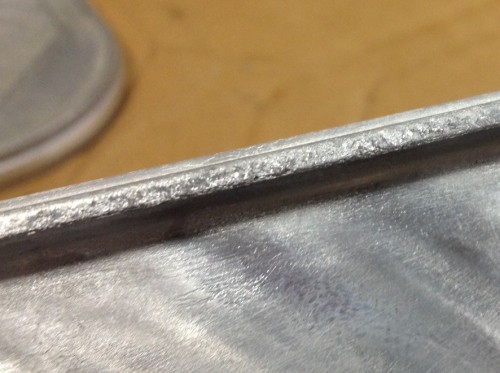

Here’s a photo of a raw cast aluminum griddle. You can see the rough spot on the rim; this wouldn’t look nice if we didn’t do some work to it, so it’s a candidate for the deburring machine.

These photos were shot during the very first startup of our vibe deburr machine. Normally we wouldn’t have so many people observing the process, but it’s a fairly exciting event for a factory to fire up a new piece of machinery that everyone’s been anxiously awaiting for more than a year! These machines are highly customized and take more than 6 months to build. As we get the machine running smoothly, there will only be one or two people required to run it (as opposed to the dozen or so in these photos!) Please forgive our enthusiasm.

Raw cast parts are loaded onto a conveyor belt which takes them up to the top of the machine and drops them into the tumbling barrel.

Inside the barrel, there is a large screw which turns and keeps the parts moving through the machine. The tumbling medium is comprised of pyramid-shaped ceramic “stones” and lots of water, which serve to polish the sharp or rough edges down as the cast part travels through the tumbler.

As you would imagine, this is not a quiet machine. Think of what it might sound like if you turned on your kitchen sink garbage disposal and dropped a crescent wrench down into it, and then multiply that decibel level by about threefold. Earplugs are definitely a necessity if you’re in the vicinity of this machine in operation! Tumbled griddles come out the other side and the loose ceramic pebbles fall through the conveyor belt to be returned into the tumbling chamber. (Good news: both the pebbles and the water circulate back through again and again, so it’s an efficiently and cleanly run process without much waste…just a bit of ceramic grit and aluminum grit, which gets filtered out in very fine paper filters and disposed of properly).

Griddles then travel through a washing process which cleans them with water. An air knife removes most of the water from them as they progress along.

Next, the griddles enter a very hot oven which dries up what little water droplets might be remaining on the parts. And now, the griddles are ready to head to our coatings department for an application of our premium PFOA-free nonstick coating. We were all giddy with excitement to watch this much-anticipated machine in action. For a company such as ours, which prides ourselves on being vertically integrated in every way that makes sense, it’s a great step forward to add a machine like this to our fleet of production equipment.